Product Application | Building a stable and efficient communication foundation for the metallurgical industry

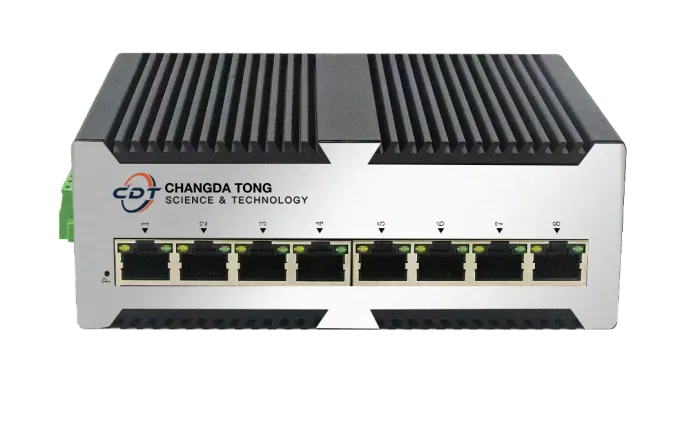

Beside the furnaces and rolling mills in metallurgical production, high temperatures, dust and electromagnetic interference interweave to form a harsh industrial environment. In the face of potential production halts or even safety hazards caused by network disruptions, Tianjin Changdatong Technology Co., LTD. 's industrial-grade switches, designed with high reliability, have built a solid communication defense line for metallurgical enterprises, facilitating the stable operation of intelligent production.

Communication challenges in metallurgical production

The metallurgical workshop environment is complex, and the equipment is exposed to extreme temperatures, severe vibrations and chemical corrosion for a long time. Traditional network devices are prone to frequent failures due to insufficient heat dissipation and weak anti-interference ability, resulting in data transmission delay or interruption, which directly affects the accuracy of process control and production efficiency. Metallurgical enterprises urgently need communication equipment optimized for industrial scenarios to ensure seamless connection of real-time data and guarantee the continuity of production.

Respond to challenges with technology and safeguard production with stability

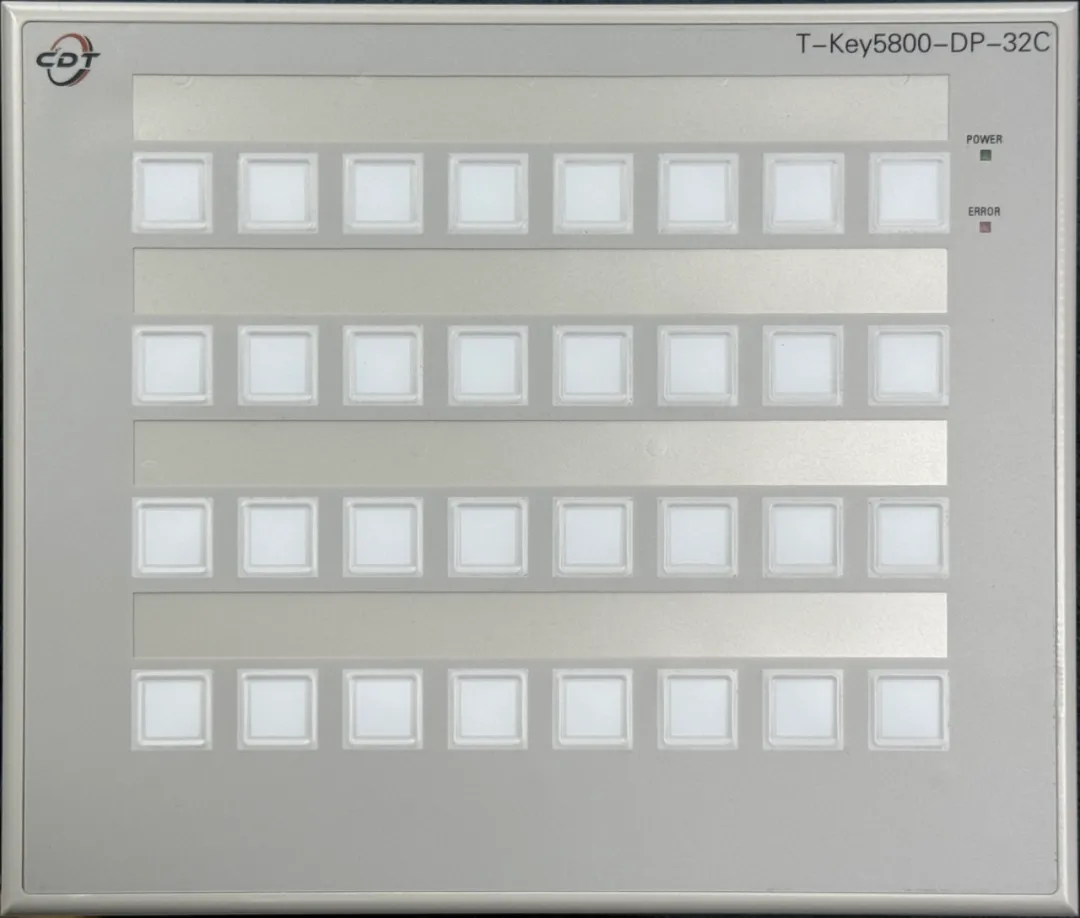

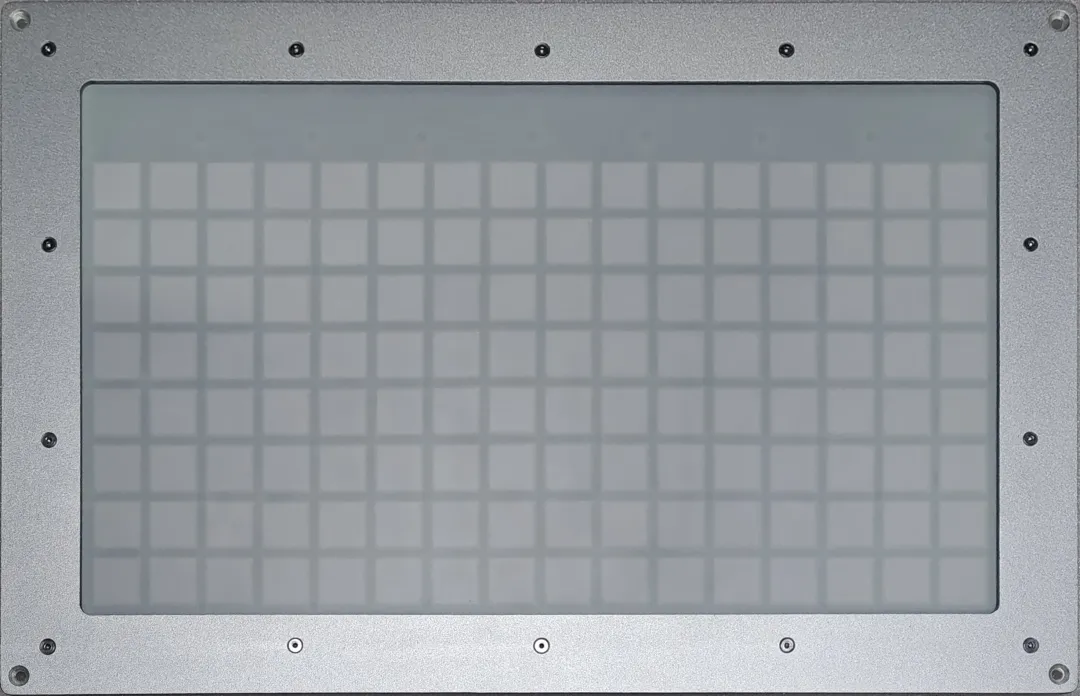

Changdatong Technology's industrial-grade switches are fully adapted to the demands of the metallurgical industry, from hardware to protocols:

Environmental adaptability upgrade

It supports wide-temperature operation from -40℃ to 80℃ and is suitable for the extreme conditions of alternating hot and cold in metallurgical workshops

The metal casing and IP40 protection design effectively prevent dust, moisture and corrosive gases from entering

Fanless silent cooling avoids malfunctions caused by dust accumulation and ensures the long-term stable operation of the equipment

Network resilience enhancement

The fault recovery time is less than 20ms. In case of network failure, the backup line will be automatically switched to ensure continuous production without interruption

It has passed the international EMC/EMI certification and maintains stable signal transmission even in a strong electromagnetic interference environment

Balance safety and intelligence

Supports industrial protocols and secure access control, meeting the high-standard networking requirements of systems such as DCS and SCADA

The dual power supply redundancy design provides continuous power supply guarantee for key process sections and eliminates the risk of unexpected power outages

Changdatong switches have been deeply integrated into multiple core links of metallurgical production:

Blast furnace monitoring system: Real-time transmission of temperature and pressure data to facilitate precise regulation of smelting parameters;

Continuous casting and rolling production line: Build a low-latency communication network to enhance equipment coordination efficiency and automation level;

Safety monitoring network: Stably connect gas sensors with monitoring terminals to achieve danger early warning and remote response.

Stand firm on quality and move forward with innovation

At present, Changdatong Technology has deepened cooperation with many globally renowned metallurgical enterprises. Its industrial communication equipment has been applied on a large scale in the core processes of metallurgy, promoting the industry to reduce its reliance on external technologies and providing strong support for the industry to build a secure and controllable communication network.

Tianjin Changdatong Technology Co., LTD

Please first Loginlater ~